Ever heard of additive manufacturing? No? What about 3D printing? Additive manufacturing and 3D printing are the same thing. Both terms refer to the process of making a three-dimensional object out of anything you can think of. Want to create shoes, accessories, tools, gifts, or gifts? No problem. You can do so using plastic, metal, nylon and over a hundred other materials.

3D Printing works by laying down many successive thin layers of material until the desired object is complete. The actual term for this process is “additive manufacturing”. Additive manufacturing simply refers to this technology of sequential layering that is used to create objects. “3D printing” is the common term in use because it is much easier than saying you are going to “additively manufacture” a toy.

When Was 3D Printing Invented?

While 3D printing is a hot topic these days, it actually isn’t new a new invention. The technology actually came about in the 1980s. But, at that point of time, it was only popular among those in the engineering, architecture and manufacturing industry. While the term 3D printing is still new for some people, manufacturers have, for decades, been using these printers to create prototypes for traditional manufacturing. But of course the technology back then was slow and expensive. Not anymore though. Now, popular brands are using 3D printers to create prototypes for shoes, accessories and other objects while architects are using it to create models of their projects rather than cutting cardboards and pasting it together.

SEE ALSO: 3D Printing in Malaysia: What You Should Know

How to 3D Print?

Understanding the concept of 3D printing is not as complicated as you think. It is almost the same as printing a document from a normal printer, except here you are using materials such as plastic, metal, nylon and even concrete to create an object. Now, a normal inkjet printer will print your document in one layer, but a 3D printer will stack layers of materials on top of each other to create a complex structure, i.e., the object of your choice. Still confused? Imagine you are making lasagne for dinner. To complete this meal, you will have to do it layer by layer, from the bottom up, until you have the finished product/dish.

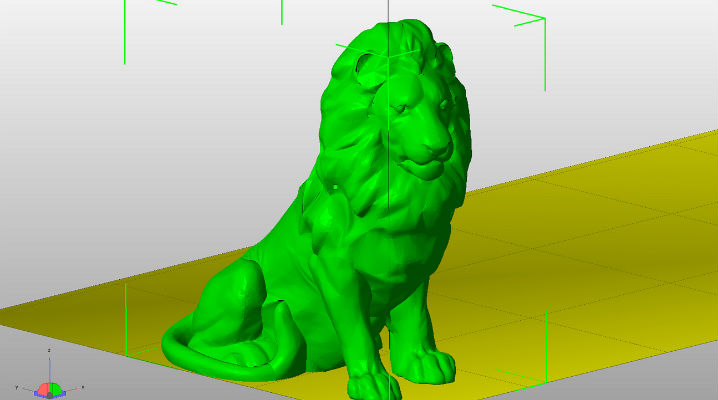

To print your desired object, you need a 3D printer (obviously) and a program to create a CAD (computer aided design) file which acts as instructions or blueprints for your 3D printer. The CAD file can be created by using a 3D modelling program such as Google SketchUp, 3Dtin, Blender, OpenSCAD, Tinkercad, and more. You need to use either one of the computer programs mentioned above to design your object. That file will then be converted to an STL (STereoLithography) file format and sent to your 3D printer. The software you use will dissect your file/design and sort of slice your design into various horizontal layers. The printer will read the file, and lay down layers of liquid, powder, paper or sheet materials to build the object. The layers will be printed one atop another until you get your 3D object.

Why Would You Want to 3D Print?

If you broke something you liked, and it was difficult to get something exactly like it, such as your favourite pair of sunglasses, you can design it on the computer, load the STL file to your 3D printer and let the magic happen. This also works for missing or broken parts. For example, if you needed a part to fix your washing machine, instead of getting your plumber to order it from the manufacturer, you can just design it and print it. For moving parts, the 3D printer will leave sufficient gaps within the parts or fill it with a gel like liquid, which you can easily wash off to work with after printing. 3D printing is also great when you are stuck for gift ideas. Who doesn’t love a personalized gift?

3D Printing and the Future

As mentioned above, 3D printing can help you print working parts for machines and tools. A 3D printer only uses the relevant amount of materials needed and this means no waste. In the long run, more and more companies will benefit from using this.

Architects can print their models with 3D printers and designers can print their designs. Any amendments can be made to the file on your computer and reprinted again. Archaeologists can scan and print priceless artefacts to ensure the original is not destroyed because of how fragile it is.

Companies can print anything from aircraft engine parts to recreating human organs from using a human cell and even building a prosthetic limb. The medical field will change significantly from 3D printing as bioprinters can be used to print human tissues, bones and even organs

Another thing being developed right now is called building printing whereby 3D printing is used to create buildings in parts. Most of the advancements mentioned here are not in place yet, but that’s because it is currently being developed. It is only a matter of time before you can 3D print your favourite meal! But for now, one can settle for small time 3D printing at home or at computer shops offering these services, and leave the organic 3D printing for later on.

Watch this 3-minute video to see how 3D printers work:

SEE ALSO:

AND: Read more recent Tech stories on Leaping Post

Photo credit: Creative Tools / Foter.com / CC BY

"ExpatGo welcomes and encourages comments, input, and divergent opinions. However, we kindly request that you use suitable language in your comments, and refrain from any sort of personal attack, hate speech, or disparaging rhetoric. Comments not in line with this are subject to removal from the site. "

This is very cool and exciting stuff. I can imagine the day when a 3D printer in a home becomes common.